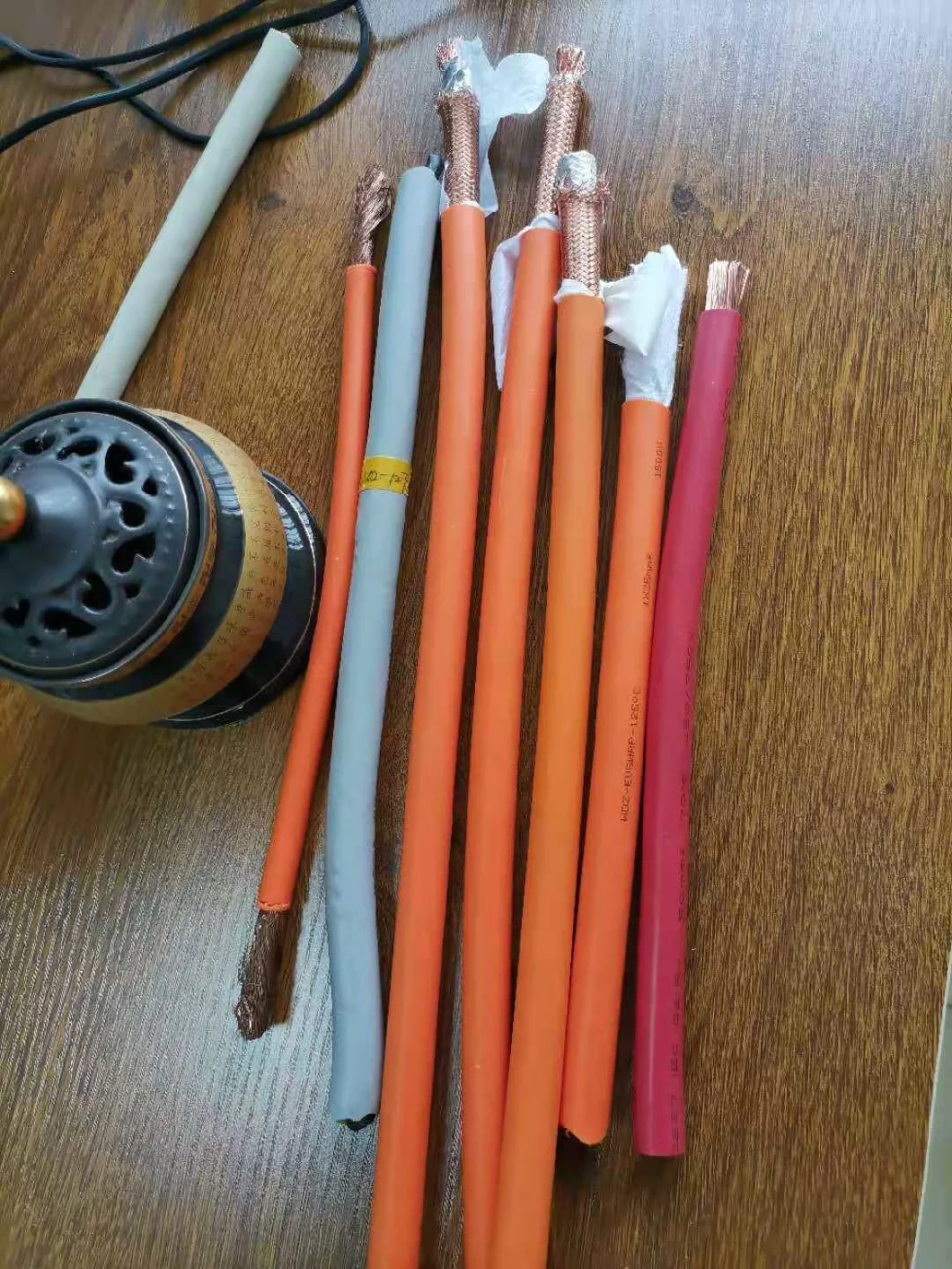

OEM Electrical Electric Power Wire Cable for New Energy Storage Wire Wiring Harness

| The era of fuel vehicles will eventually pass. Under the triple pressures of policy, energy and environment, new energy vehicles have become the general trend. New energy cables are the abbreviations for wires and cables used in new energy vehicles. Because of the high voltage and high current in the new energy vehicle and the limited space, the charging pile cables are exposed outdoors for a long time, and the particularity of the use environment puts very strict requirements on the performance of the cable materials. New energy automobile cables need to have high and low temperature resistance, oil and water resistance, flame retardant, tear resistance, insulation, and UV aging resistance. Commonly used materials include TPE, TPU, XLPO, NBR+PVC, neoprene, silicone rubber, etc. |

| 1. TPE TPE thermoplastic elastomer, also called thermoplastic rubber TPR. The categories of TPE are: styrene, olefin, diene, vinyl chloride, polyester, ester, amide, organic fluorine, silicone and ethylene (TPS, TPU, TPO, TPV, etc.) ). Most of the currently used elastomers refer to SEBS as the base material. TPE material used in charging cable Advantages: simple processing technology, low density, moderate price, and the overall cable is very flexible, which can meet the requirements of various existing standards. Disadvantages: Most of them contain unsaturated bonds, poor temperature stability; low oil resistance, especially gasoline; poor weather resistance, poor thermal stability of materials used for a long time, material mechanical properties drop a lot under high temperature conditions, high risk of cracking in outdoor use; intolerance Dirty and sticky hands. Working temperature: cold resistance -50 degrees; temperature resistance within 120 degrees. 2. TPU TPU, the thermoplastic polyurethane elastomer, has a molecular structure of polyester type and polyether type, composed of rigid blocks and flexible segments. In the processing process, injection molding accounts for more than 40%, and extrusion molding is about 35%. ; The length of the spring can reach 2-6 times of the original spring length. The charging pile cable polyurethane sheath material is made of TPU resin as the main material, added with environmentally friendly or halogen-free flame retardants, antioxidants and other additives through mixing, plasticization, and granulation. It is flexible and resistant to rolling. Withstand voltage, high temperature pressure, aging resistance, acid and alkali resistance, salt spray resistance, waterproof and other characteristics. Advantages: Excellent high-tension, high-tension, toughness and aging resistance characteristics, environmentally friendly materials. Disadvantages: At present, domestic processing is difficult, raw material enterprises are few, and the cost is high. Working temperature: cold resistance -40 degrees; temperature resistance within 150 degrees. 3. Polyvinyl chloride elastomer PVC polyvinyl chloride cable, based on polyvinyl chloride, can be adjusted by adding different amounts of plasticizer to adjust its flexibility and reduce its "vitrification" temperature, thus having good flexibility and increasing plasticity. Make it easy to process and shape. After cross-linking, the chain segments form a network structure, and the elastic stretch length can reach 2-4 times the original spring length. Advantages: flame-retardant and insulating, acid-resistant, oil-resistant, easy to process and modify, and cheap. Disadvantages: There will be black smoke and HCl gas during combustion. Working temperature: cold resistance -40 degrees; temperature resistance within 105 degrees (according to customer requirements). 4. Silicone rubber The AGR silicone rubber cable made of silicone material has good elasticity, and the suitable temperature range is -60ºC-200ºC. Voltage: 300/500V Conductor material: The process principle is similar to that of rubber, and it is processed by mixing and high-pressure molding. Advantages: heat resistance, cold resistance and weather resistance, waterproof, good flexibility, easy to install. Disadvantages: not resistant to oil, poor tear resistance, and more expensive. Working temperature: cold resistance -40 degrees; temperature resistance within 200 degrees. 5. XLPE XLPE cross-linked polyethylene is a kind of physical or chemical method to change the molecular structure of XLPE insulating material from linear molecular structure to net-like linear structure. PE is the base resin and silane is the bridging material. Advantages: higher cross-linkability, better flexibility, good insulation, light structure, easy installation, and cheap. Disadvantages: poor heat resistance, difficult to control the color difference between batches. Working temperature: cold resistance -50 degrees; temperature resistance within 100 degrees. |

| Product Name | Wiring Harness |

| R&D Ability | Customized wiring according to your samples or drawings. |

| Cable Materials | Wire harness can be UL/CSA,CE, VDE,SAA,CB etc |

| Cable Certificate | UL, CSA, VDE, CE, RoHS, ISO9001 |

| Connector Type Range | Deutch, JAE, Hirose, Molex, AMP, LEMO, etc, base on customer's request |

| Application | Industrial, Automation, Medical, Automotive, Consumer Electronics etc. |

| Cable Preparation | Trimmings, Stripping, Tin coating, Twisting |

| Cable Color & Length | According to the customers' requirements |

| Application | Automotive,Electrical, Industry, Medical |

| Service | OEM and ODM products are acceptable |

| Design Ability | We can supply samples, OEM & ODM are welcome. |

| MOQ | Small MOQ and trial order are welcome. |

| Samples | Samples confirmed first before mass production |

| Engineering service | Development and early Design in support, analysis 2D or 3D drawings |

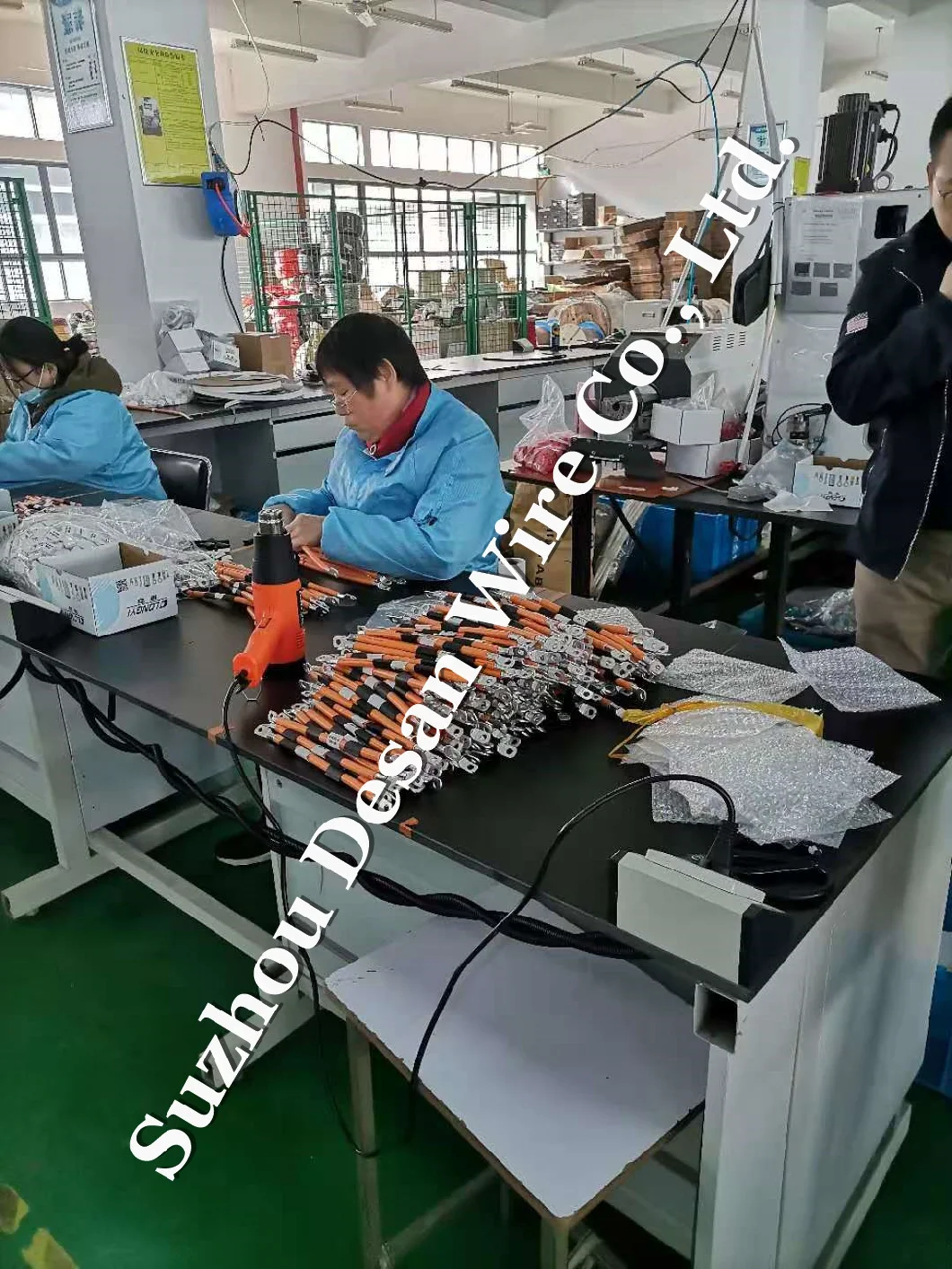

| Final assembly | Bolting,Binding,Shrinking,Extruding,Strain Relief Molding,Inner and Outer Molding |

| Quality Control | 100% electrical and electricity performance test,100% inspected before dispatching. |

| Packaging | Inner PE bags with label, outside carton |

| Delivery Time | 10- 45 days, on-time delivery |

| Payment | T/T, Paypal, Western Union, L/C |

| We specialize in R & D, production and processing of various middle and high-end wire harnesses cables, providing customers with strong and competitive industrial special cables, production and final testing services. We also offer contract manufacturing, engineering service, designing service, assembling service. Please just send us your inquiry with detailed specifications, ideas and samples if you have. | The application industries include: 1)air conditioner wiring harness 2)washing machine wiring harness 3)refrigerator wiring harness 4)automobile wiring harness 5)electric vehicle wiring harness 6)battery car wiring harness 7)transformer wiring harness 8)robot wiring harness 9)treadmill wiring harness 10)motor wiring harness 11)network and communication wiring harness 12)communication wiring harness 13)medical wiring harness 14)air purifier wiring harness Wait. 15) New Energy Vehicle Wire Harness Our design engineers will work with you to provide customers with high-quality products and first-class service is our ultimate goal. |

| 1. Q: Are you a factory or a trading company? A: We are a factory with more than 10 years' manufacturing experience. 2. Q: What standard of your products? A: We will manufacture according to your required standard. 3. Q: Where is your factory located? A: 4# Chuangxin Middle Road, Yinghu Industrial Park, Wangting Town, Xiangcheng Distric, Suzhou City, P. R. China, Suzhou, Jiangsu, China 4.Q: Would you please send a sample for us to check? A: We can provide samples of mature technical processing line; while special types shall be treated with technical appraisal before confirmation of sample availability. And samples can be provided free of charge or at a cost price depending on specific sample type. Any fee for transportation of the sample shall be assumed by customers. 5. Q: Can your company accept customized orders? A: Yes, we can produce based on customization requirements practicable for us. 6. Q: What is your payment term? A: We have several payment terms for you, T/T, Western Union, etc. 7. Q: What about the lead time for mass production? A: Frankly speaking, it depends on the order quantity and the seasons. 8. Q: Do you have the mentioned wire in stock? A: After knowing what you need, we will check with our warehouse. If your order quantity reaches 6800m/size/color can arrange production. 9. Q: How about your after-sales service? A: Any after-sales inquiry will be kindly treated within 24 hours once received written notice from any client via e-mail, express mail, etc. Your request will meet our active response to furnish you with satisfying solution. 10:Q: What is your contact information? A:The contact information as below: Contact Person: Brian Ren Company Name: Suzhou Desan Wire Co., Ltd. Address: 4# Chuangxin Middle Road, Yinghu Industrial Park, Wangting Town, Xiangcheng Distric, Suzhou City, P. R. China, Suzhou, Jiangsu, China Post Code: 215155 Mobile & Whatsapp: 0086 18068169653 |

Custom Electrical Wire Harness

Industrial Wire Harness

Medical Wire Harness

Automotive Wire Harness

Wire Harness Cable

Wire Harness Assembly

Molex Connector

Automotive Cables Fuse Block Wire Harness

Wiring Harness with Connectors