Male and Female 5.5*2.1mm DC plug with nut used for power cable assembly

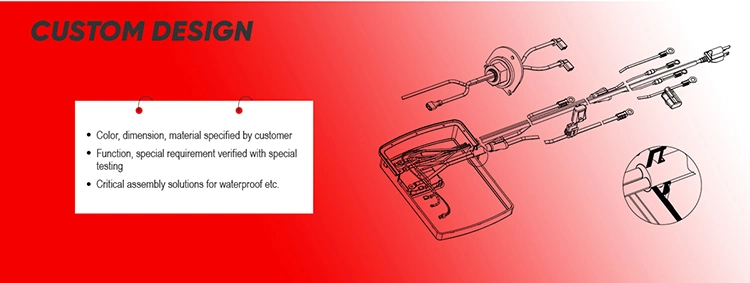

The molded strain relief used for wire branching function, which used for customer assembling to their counterpart. So all the cable SR molded size, shape, materials processed following customers' requirement.

Edgar can provide quick-turn injection molding by many types of materials, like ABS, PA66, PBT, TPU, TPE, PVC, PE, NYLON 6, PC, silicone, TPU, etc. Our advantages in internal prototyping, bridge tooling and short-run manufacturing, which can eliminate the costly and time-consuming for customers a lot.

After customer approved 3D drawing, we can test it by 3D printer first, then move on for formal tooling once confirmed ok. And all related materials, logo, color or finishes can be chosed as customers' requirement.

We have developed a tradition of high-tech engineering, prototyping, and quality Custom Cable Assembly manufacturing at very competitive pricing. Also with professional flow chart (wire cutting-stripping-copper twisting-crimping-crimping 100% inspection-soldering-molding-asssembling-braiding-testing-FQC100% -OQC) , which can help us support customers with stable quality.

Model No.: SR (Strain Relief)

Material: PA66, tined plated compliant ROHS,

Working temperature: -20~80°C

Over-molding: customize

Voltage: 12V for car and 24V for heavy vehicle

Professional project management and part design / modify

- Supply customized wire harness including back-up accessories

Export to all over the word by FOB or other customer specify request

- Quality ensure by ATF16949 & ISO9001 quality manage system,UL E468011& UL E468011 certified

Inquiry will be replied within 24 hours

Only manufacturer high quality cables

All cables/wire harnesses are made under IPC/WHMA-A-620B Standrad

Issue professional engineering drawings to customers before sampling

Quick reponce to cusomter needs

Provide advantage quotation to help customer win

Welcome high mix-low value orders

Can design commercial packing for customers

Very low delivery cost(60%-70% off by Fedex, UPS, TNT)

Packaging Details could be customized by client specified.

Normally, the lead time below for reference, the detail according to conversation:

| Quantity (PCS) | 1 - 1000 | 1001 - 5000 | >5000 | Mold/ tooling |

| Est. Time(Days) | 20 | 25 | To be negotiated | 30 days more |

International expressed by DHL, UPS, FedEx, TNT, ARAMEX and EMS etc..

Customers choice for shipping by air, sea or others.

Payment for samples/mass products shall be closing before delivery, amount above 5000 USD according to conversation in somewhere.

Strain Relief,Grommets,Waterproof assembly, Over-molding,Adding glue Multi-process cable

Strain Relief,Grommets,Waterproof assembly, Over-molding,Adding glue Multi-process cable

customer special require and design cable assembly etc..

1. Q: Can you help to design?

A: Yes, we are an ODM / OEM company, beyond we have been specializing in wire harness & Cable assembly since 1999.

2. Q: When will you start to help design?

A: We sketch simple solution for initial discussion, after quotation and order placed then start to drawing and double confirm with client for the design.

3. Q: What if quality issues occur when customer discover?

A: Our quality and engineer team will positively respond for the quality issues with 72 hours, as we are intend to make long-stand strategy with customer and the value is to provide better service.

4. Q: Do you have any standard products to cut down customers lead time for prototype and tooling cost?

A: Yes, we have developed over 1000 sets of molds and some of them can be used for customer directly. Besides, we specialize in wire harness over 20 years with more than 5000 products