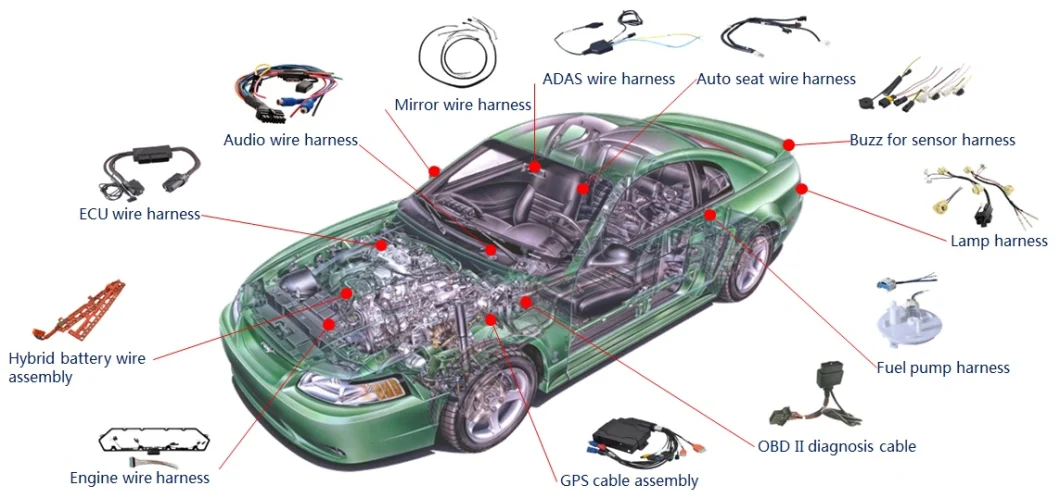

J1962 16pin OBD molding Wire Harness

1.voltage :dc 300v 5m ohm/10 ms

2.contact resistance:3.0 ohm MAX

3.100% open ,Short ,Mis-Wirs Testing

SAE standards documents on OBD-II

- J1708 - Defines a standard used for serial communications between ECUs on a heavy duty vehicle and also between a computer and the vehicle.

- J1850 - Defines a serial data protocol. There are two variants- 10.4 kbit/s (single wire, VPW) and 41.6 kbit/s (two wire, PWM). Mainly used by US manufacturers, also known as PCI (Chrysler, 10.4 kbit/s), Class 2 (GM, 10.4 kbit/s), and SCP (Ford, 41.6 kbit/s)

- J1939 - Defines a data protocol for heavy duty commercial vehicles

- J1962 - Defines the physical connector used for the OBD-II interface.

- J1978 - Defines minimal operating standards for OBD-II scan tools

- J1979 - Defines standards for diagnostic test modes

- J2012 - Defines standards trouble codes and definitions.

- J2178-1 - Defines standards for network message header formats and physical address assignments

- J2178-2 - Gives data parameter definitions

- J2178-3 - Defines standards for network message frame IDs for single byte headers

- J2178-4 - Defines standards for network messages with three byte headers*

- J2284-3 - Defines 500 kbit/s CAN Physical and Data link layer

- J2411 - Describes the GMLAN (single-wire CAN) protocol, used in newer GM vehicles. Often accessible on the OBD connector as PIN 1 on newer GM vehicles.

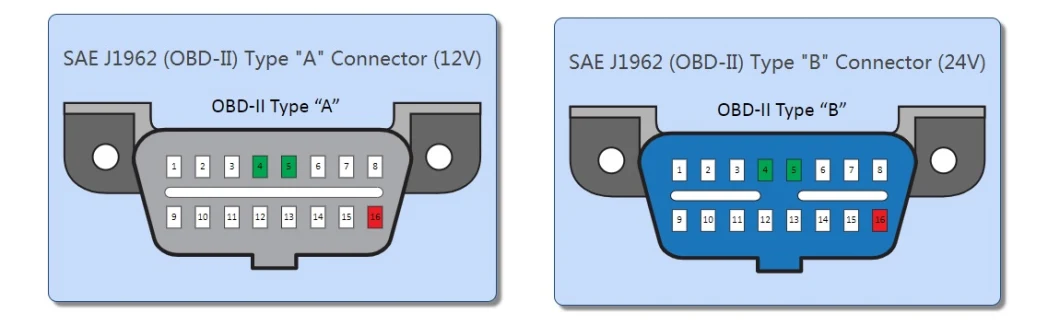

J1962 connector:

The SAE J1962 specification provides for two standardized hardware interfaces, called type A and type B. Both are female, 16-pin (2x8), D-shaped connectors, and both have a groove between the two rows of pins, but type B's groove is interrupted in the middle. This prevents the insertion of a type A male plug into a type B female socket while allowing a type B male plug to be inserted into a type A female socket.

The type A connector is used for vehicles that use 12V supply voltage, whereas type B is used for 24V vehicles and it is required to mark the front of the D-shaped area in blue color.

| Pin Number | Description |

|---|---|

| 1 | Manufacturer Discretionary |

| 2 | SAE J1850 Bus + (VPW / PWM) |

| 3 | Manufacturer Discretionary |

| 4 | Chassis Ground |

| 5 | Signal Ground |

| 6 | CAN High (ISO 15765-4 and SAE J2284) |

| 7 | ISO 9141-2 / ISO 14230-4 K Line |

| 8 | Manufacturer Discretionary |

| 9 | Manufacturer Discretionary |

| 10 | SAE J1850 Bus - (PWM-only) |

| 11 | Manufacturer Discretionary |

| 12 | Manufacturer Discretionary |

| 13 | Manufacturer Discretionary |

| 14 | CAN Low (ISO 15765-4 and SAE J2284) |

| 15 | ISO 9141-2 / ISO 14230-4 L Line (Optional) |

| 16 | Vehicle Battery Power:

|

Material: PA66, tined plated compliant ROHS,

Working temperature: -20~80°C

Over-molding: customized

Pitch: 4mm

Voltage: 12V for car and 24V for heavy vehicle

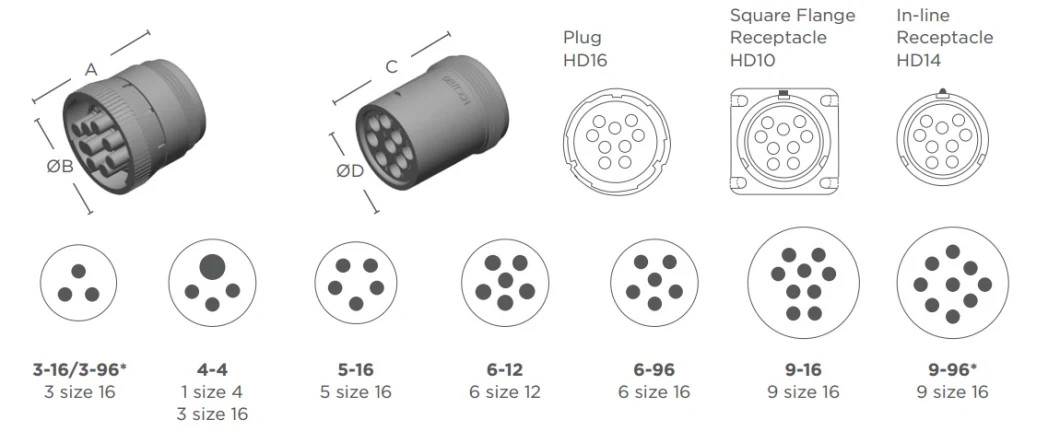

DEUTSCH HD10 series connector

The HD series is an environmentally silicone rubber sealed, thermoplastic cylindrical connector, which is designed to be a faster, easier, trouble free assembly diagnostic connector in heavy-duty industry like truck, bus, cross-country vehicle,crane and forklift etc. When mated, the contacts are protected from water, dust, lubricating oils, fuel, road salt, grease, mud and other contaminants encountered.

Operating at temperatures -40ºC to +125ºC, no Cracking, Chipping or leaking after 20 test cycles from -40ºC~+125ºC.

No unlocking or unmating and exhibits no mechanical or physical damage after sinusoidal vibration levels of 20 G's at 10 to 2000Hz in each of the three mulually perpendicular planes for 2 hours. Force testing report as below shows

IP68 rating, waterproof withstand immersion under 1.2 meter of water for 24 hours.

| Cavity | Overall Length A | Overall Height ØB | Overall Length C | Overall Height ØD |

| 3 | 1.609 (40.87) | 1.069 (27.15) | 1.639 (41.63) | .851 (21.62) |

| 4 | 1.639 (41.63) | 1.595 (40.51) | 1.639 (41.63) | 1.281 (32.54) |

| 5 | 1.609 (40.87) | 1.218 (30.94) | 1.639 (41.63) | 1.001 (25.43) |

| 6 | 1.619 (41.12) | 1.453 (36.91) | 1.639 (41.63) | 1.141 (28.98) |

| 9 | 1.609 (40.87) | 1.593 (40.47) | 1.639 (41.63) | 1.281 (32.54) |

HD10 series

| Position | Contact Size | Rear Threads | Plug | Receptacle Inline | Receptacle Flange |

| 3 | 16 | no | HD16-3-16S | HD14-3-16P | - |

| yes | HD16-3-96S | HD14-3-96P | HD10-3-96P | ||

| 4 | 4/16 | yes | HD16-4-4S | - | HD10-4-4P |

| 5 | 16 | no | HD16-5-16S | HD14-5-16P | HD10-5-16P |

| 6 | 16 | yes | HD16-6-96S | HD14-6-96P | HD10-6-96P |

| 6 | 12 | yes | HD16-6-12S-B010 | HD14-6-12P | HD10-6-12P |

| 9 | 16 | no | HD16-9-16S | HD14-9-16P | HD10-9-16P |

| yes | HD16-9-96S | HD14-9-96P | HD10-9-96P | ||

| 9 (J1939) | 16 | yes | HD16-9-1939S | HD14-9-1939P | HD10-9-1939P |

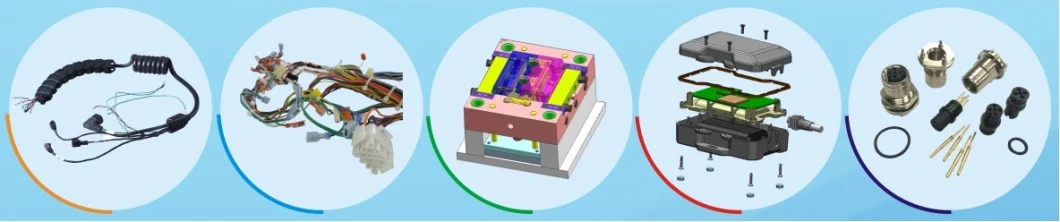

COMPANY PROFILE

☆ Privately held company, established in 1999

☆ Sales volume over 16 Million USD since 2017

☆ OEM & ODM company, with employees more than 250 persons, 7260 square-meters in size

☆ Service for economical solutions and innovative wire harnesses design & manufacturing

☆IATF16949 (2016) & ISO 9001 (2015), and UL certified supplier with wiring No. E468011 & cable No. E479323

CERTIFICATION

Q&A

1. Q: Can you help to design?

A: Yes, we are an ODM / OEM company, beyond we have been specializing in wire harness & Cable assembly since 1999.

2. Q: When will you start to help design?

A: We sketch simple solution for initial discussion, after quotation and order placed then start to drawing and double confirm with client for the design.

3. Q: What if quality issues occur when customer discover?

A: Our quality and engineer team will positively respond for the quality issues with 72 hours, as we are intend to make long-stand strategy with customer and the value is to provide better service.

4. Q: Do you have any standard products to cut down customers lead time for prototype and tooling cost?

A: Yes, there are over 1000 sets of molds and some of them can be used for customer directly. Moreover, Edgar is specialized in wire harness over 20

years with 5000+ products

CONTACT US